Fire Safety, Part 2 – Types of Protection; Preventing and Dealing With the Fires Onboard

Find out more in the first part

Passive fire protection

Fires that occur on boats or in marinas can spread quickly and present unique response challenges due to hazardous conditions and limited access. Generally, the best defense against fire is prevention. Passive fire protection, known as PFP, is an essential part of any fire plan.

PFP includes fire protection and fire detection. The primary goals of utilizing PFP are to minimize the spread of fire and smoke by isolating them in a single compartment and protecting escape pathways for critical escape methods.

Examples of passive systems include:

- flammable-resistant ceilings and roofs

- fire doors, windows, and wall assemblies

- fire-resistant coatings, and other fire and smoke control assemblies.

They can also incorporate active components such as fire dampers. The main elements of the fire prevention system are outlined in the table below.

| Elements of passive fire protection |

|---|

| Structural fire protection (hull, superstructure, bulkheads and decks) |

| Restrictions on the use of combustible materials |

| Insulation of exhaust systems |

| Venting of cargo spaces, fuel tanks and pump rooms |

| Means of escape |

| Minimum stairway sizes |

| Fire detection and alarm systems |

| Fireman systems (seawater supply) |

| Fixed fire extinguishing systems |

| Portable and semi-portable extinguisher requirements |

| Approved machinery, equipment and installation. (Brady 1980) |

Besides the equipment and architectural prevention setups, a large role in fire prevention plays fire prevention education and training for the crew. Most fires are preventable; in other cases, the damage can be significantly minimized if the crew members are properly trained and know their roles and responsibilities. The crew has to be timely educated and the supervisors have to have a curriculum of crew preparation and follow it. There should be a continuous system of training, both formal and informal, and periodic inspection of skills and knowledge. Crew responsibilities should also include preventive maintenance, including lubrication and care, testing and inspection, repair or replacement, and record-keeping for all the elements of machinery and equipment. (Brady 1980)

Depending on the Bering boats’ size and class requirements, the next passive fire protection and firefighting equipment is installed throughout the vessels:

– Fire-resistant insulation. Depending on the location and size of the boat, the thickness and placing of the protective materials differ. For example, Rockwool around the engine rooms is over 10 cm thick while for other cabins, especially for the risk-free areas, its thickness decreases. This way we save space and provide our clients more comfort in the living quarters.

– Bulkheads and fire-resistant doors. Watertight doors with fire insulation inside produced by Bofor can resist fire for up to 30 minutes. Specially designed bulkheads are enough to keep the fire from spreading to the master cabin.

Active fire protection

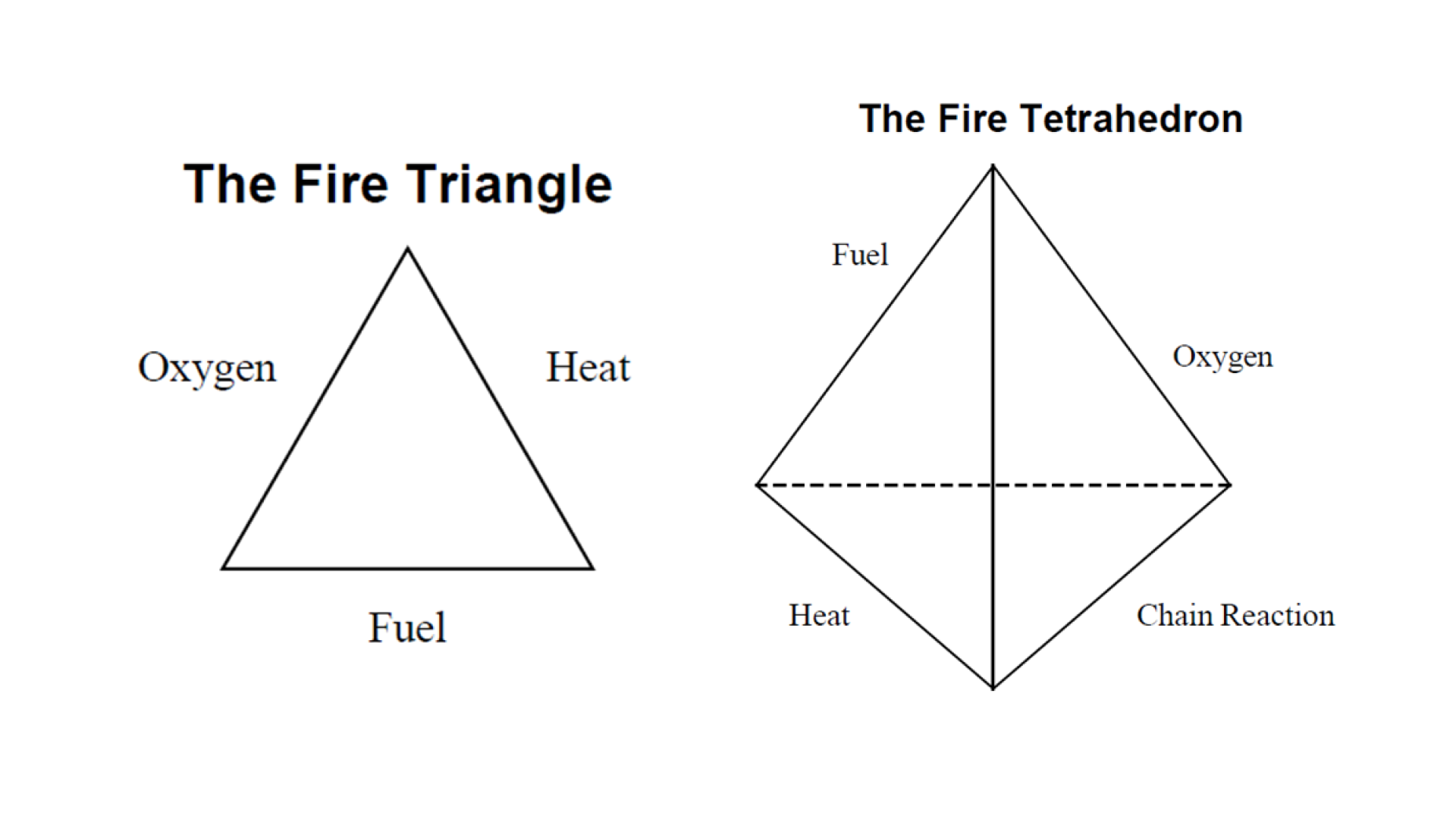

If a fire occurs regardless of all the precautions, active firefighting measures should be taken. Once a fire starts, it will continue to burn as long as there is something to burn. There are three necessary requirements for starting and sustaining any fire: oxygen, heat, and fuel. If any of the sides of this so-called fire triangle is removed, the fire will die out. Concept of the fire tetrahedron includes one more component: the chain reaction caused by the oxidation process. The graphic representation of the fire triangle and fire tetrahedron are provided below.

A basic strategy when responding to a fire on a ship involves four steps – locating, informing, containing, and then extinguishing a fire. Prior to taking active measures, one needs to properly classify the fire, which will allow fighting it more effectively.

Bering Yachts follows The United States classification (NFPA 10), which classifies the type of fire according to the materials and systems that can be involved. NFPA describes five main classes of fire (A-F), involving solid fires, liquids/gas fires, electric, metal, and cooking oils and fats as the main possible triggers of a fire on board.

It is important to understand that a yacht fire may start off as any class, and they end up being multiple-class fires because of the chemicals and the fuels onboard. Therefore, the extinguishing agents must be employed properly and correct firefighting techniques must be used. Also, all the necessary appliances should be located at their appropriate spots, and be kept in working condition.

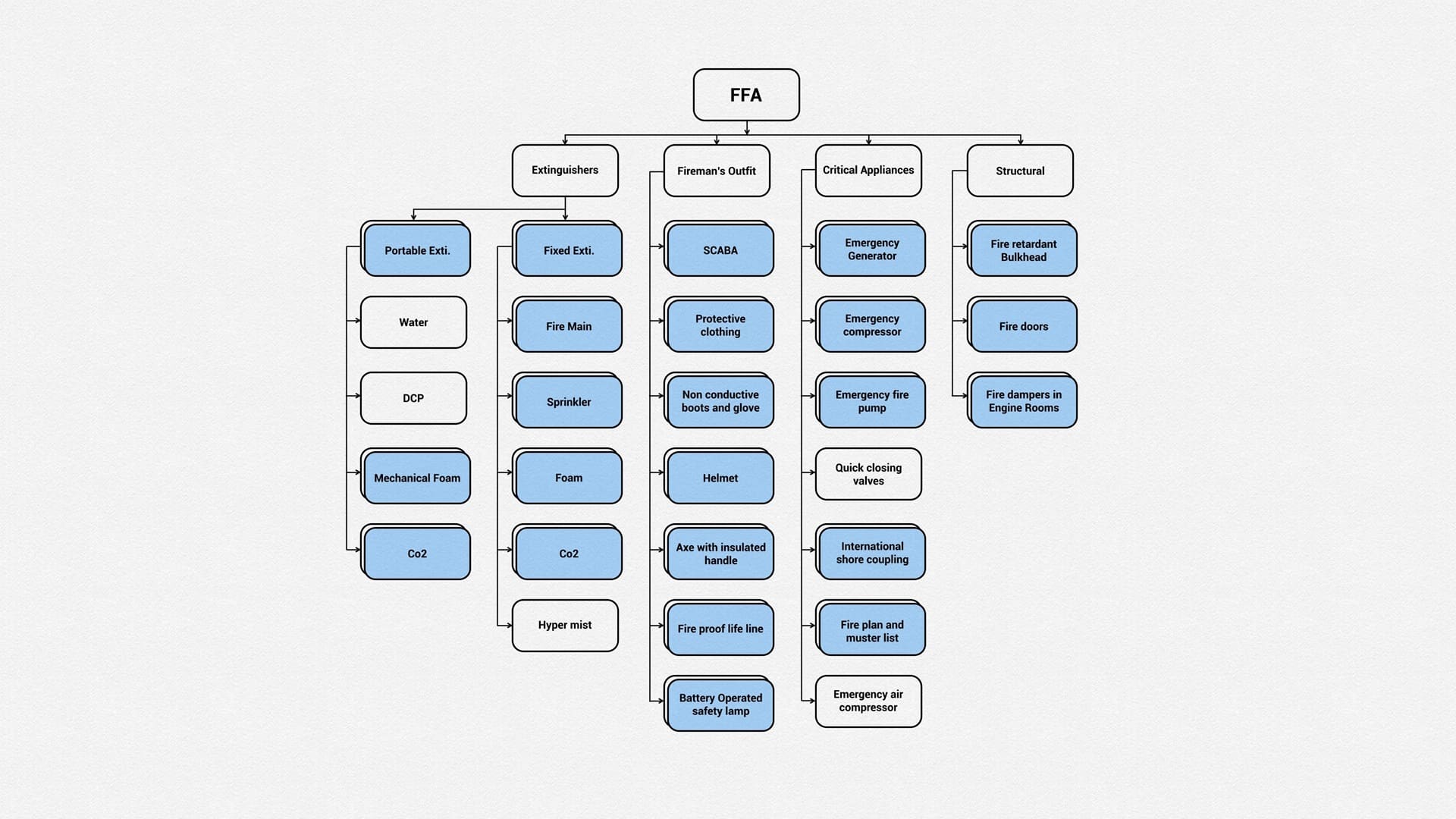

Firefighting appliances (FFA) onboard can be categorized into 4 groups:

- Extinguishers, portable and fixed

- Fireman’s outfit

- Critical appliances, such as reserve and emergency pumps and generators

- Structural, including fire doors, dampers, etc.

A ship is approved to sail in international waters only if it is constructed per the fire safety system code and carries required FFA, approved by the concerned authority.

The list of active fire-fighting appliances on Bering yachts includes:

– Emergency fire pumps that can deliver seawater even in the case of an energy shutoff.

– A Poseidon joint-monitoring safety system. A ship control system regulates all the electronic equipment onboard, including fire monitoring systems and smoke and fire detectors.

– Fire extinguishing system in the engine room using aerosol fire suppression technology. Modern approved halon replacement and hydrofluorocarbon (HFC) alternative, Stat-X fire suppression system answers all the possible firefighting challenges. It generates an ultra-fine suspension of highly ionized potassium fire-fighting particles upon actuation thus inhibiting the fire chain reaction. Agent particles also absorb heat from the fire and form inert gases upon decomposition. Clean-up of the post-fire area does not have any chemical or environmental hazards due to the firefighting agent. According to the producer, it is by far the most efficient fire suppression agent by weight. It is activated automatically and manually, by pressing the emergency buttons out of the boat on the maindate.

– Enough fire extinguishers of different classes located throughout the boat according to their class and safety recommendations.

– Safety and evacuation plan and also written guidelines on the crew fire safety training. Captain’s responsibility is to organize proper training and conduct regular inspections of the equipment, fire safety devices and crew knowledge about the firefighting and safety protocols and activities.

A full list of approved FFA is outlined in the diagram below. The FFA that are present onboard Bering boats are marked blue.

Materials and fire safety

There are a number of hazards produced by a fire, including flames, heat, gasses and smoke. Each of these combustion products can cause serious injuries or death during and even after the fire. All of them should be considered in the overall scope of fire-fighting arrangements onboard a vessel.

Bering has previously covered some of the fire hazards of different shipbuilding materials in an article on Steel. While steel is almost non-burning, aluminum does melt at high temperatures, the fiberglass presents a higher degree of fire danger. Composite materials, as well as wood, textiles, fibers, and rubber, belong to the materials that produce class “A” fires. Fiberglass fire usually spreads quickly and produces a lot of smoke.

It is generally recognized that many fire casualties have suffered or died from exposure to gaseous combustion products rather than from heat or external burns. In the process of burning fiberglass, harmful vapors of hazardous compounds are released, causing respiratory problems. Below is the list of the components and the negative effects they might cause.

| Burning fiberglass emissions and their effect: |

|---|

| Carbon monoxide: displaces oxygen in the blood and deprives the heart, brain and other vital organs of oxygen; causes dizziness, confusion, unconsciousness and death |

| Formaldehyde: immediately causes eye irritation, headaches, skin irritation and can cause heart and respiratory death- |

| Styrene: suspected carcinogen; toxic by inhalation; eye and mucous membrane irritant |

| Acetone: skin and severe eye irritant; inhalation causes systemic effects in respiratory system, muscle and blood functions |

| Methyl ethyl ketone: inhalation especially affects respiratory system; severe eye irritant |

| Phosgene: upon inhalation combines with moisture to form hydrochloric acid and carbon monoxide in bronchioles and alveoli of the lungs; severe eye, skin and mucous membrane irritants. |

Depending on the fiberglass composition, these and other harmful combustion products including carbon monoxide, benzene, biphenyl, pentadiene, and toluene can be released. (Hadden 2020) Often death occurs sometime after the exposure to the toxic gasses from the aftereffects of the exposure, usually from lung injury complications. It is estimated that 55 to 80 percent of fire deaths can be traced to smoke inhalation. (Junod 1976)

Since burning of fiberglass might be a significant safety threat, Bering makes sure the composition of their boats has the most fire-safe materials and designs. Besides the limitations on use of composite materials, there are fire protection measures implemented that correspond with the international safety regulations.

As an example, a BoatU.S. Foundation ran in 2016 a set of setup boat burn exercises. You can check photos and videos on their site to see for yourself how quickly the boat burns, what black fiberglass fumes actually are and what are the aftermath of the boat fire. Boat Burn – How to Improve Boat Fire Safety

Conclusion

Ensuring fire safety is one of the main goals of the Bering team. We do all that is possible to ensure structural, design, and equipment-related protective measures. We also understand that the crew’s knowledge of the ship’s construction features, firefighting equipment, and cargo is the key to effective fire prevention and firefighting. The success of a firefighting operation—and perhaps survival—will depend on how well the crew has been trained, and how well they know and maintain their vessel and its firefighting systems. Therefore, Bering trains captains to ensure that crew fire safety education and boat inspections are done on time and thoroughly.

Engineers, boat builders, equipment producers, and the crew – we all work together to ensure your safety on the water.

Sources

- American Bureau of Shipping (ABS). Guidance Notes on Fire-Fighting Systems 2017.

- American Bureau of Shipping (ABS). Guide For Enhanced Fire Protection Arrangements 2022.

- Brady R. Marine Fire Prevention, Firefighting and Fire Safety. 1980

- BoatU.S. Your Boat’s on Fire, Now What? https://www.boatus.com/expert-advice/expert-advice-archive/2016/june/your-boats-on-fire-now-what (accessed on 25.01.2023).

- Hadden R. Combustion Related Fire Products: A Review. Prepared for the Ministry of Housing, Communities and Local Government under Contract Number CPD/004/120/109. 2020

- International Maritime Organization. FSS International Code for Fire Safety Systems 2015. ISBN: 978-92-801-1601-4

- International Maritime Organization. History of SOLAS fire protection requirements. https://www.imo.org/en/OurWork/Safety/Pages/History-of-fire-protection-requirements.aspx (accessed on 25.01.2023).

- Junod T. Gaseous Emissions and Toxic Hazards Associated with Plastics in Fire Situation. NASA. Washington, D.C. 1976.

- MarineSite.Info Fire Fighting Appliances (FFA) on Board Ship https://www.marinesite.info/2015/01/fire-fighting-appliances-ffa-on-board.html (accessed on 25.01.2023).