Noise and Vibration in Yachts and Superyachts Construction. Part 2: Tools, Implementation, and Testing

Find out more in the first part

Noise and vibration prevention tools and approaches

Among the possible solutions to meet the vibration requirements are:

- Acoustical design practices: including using relatively quiet machinery and propulsors, optimal general arrangements, and placing compartments with less stringent noise criteria closer to major noise sources. These proper acoustical practices are incorporated during the initial stage of a ship design. Sources of noise such as engines, fans, rotating equipment, to the extent possible, should be isolated and located away from work and living spaces. The crew accommodations areas should be arranged in the middle or rear of the superstructure or on the poop deck and above. Equipment that by its design or quality are lower noise and vibration should be selected instead. Though simple, these acoustical practices are effective in controlling noise and should be relatively lower in cost to implement compared to noise treatments.

- Noise predictions in ship design: using computer-generated 3D models during the initial ship design stage to make noise predictions. These models should include the complete setup and locations of machinery and other objects and settings that would affect generation, absorption, transmission, and reception of noise and vibration throughout the vessel.

- Evaluation and Selection of Noise Treatments: after the noise predictions and analysis have been carried out during the initial ship design stage, the noise treatments need to be considered even if all the noise criteria are met. It is more likely than not that additional noise treatments may be found necessary. There is a broad range of noise treatments available, including source, path, and receiver treatments. Source treatment deals with machinery, including propulsion systems and other machinery. Path treatment deals with the noise path, which is defined as the construction of the source and the receiver space and as mentioned earlier in this report, a noise path can either be structure-borne or airborne. Use of damping material and sound absorptive insulation for noise reduction, treating the source with a high transmission loss material, increasing the number of obstacles along the noise/vibration path, and use of resilient connections of the piping with machinery and structure are some of the ways to reduce the noise and vibration. Receiver treatment uses “Floating” cabins or floors to mitigate noise. A floating room has finish surfaces connected to the hull through resilient mounts. The gap or void between the false deck and structural bulkheads is partly filled with thermal and acoustical insulation such as mineral wool. The receiver space can be further treated with a high sound absorbing and high sound insulating ceiling.

The noise treatments discussed above are not the only ones available in the marketplace. There also are possible applications of noise-canceling technologies from other industries for the marine industry such as active mufflers, active mounts, noise-canceling quiet zones, and noise-canceling headsets. (Dev 2017).

There is a close relationship between the vibrations of structures and the ship’s acoustics, hence some of those solutions for noise can also be used to satisfy the vibration requirements, especially for structure-borne noise. The vibration-reducing approaches include:

- Vibration Design Practices: just like with the noise, it is done during the initial stage of ship design. Such practices include selecting relatively low vibration machinery and providing sufficient propeller clearances.

- Selection of Low Vibration Machinery: installing moment compensators with the engine plays an important role in reducing vibration.

- Providing Propeller Clearances: As a rule-of-thumb, this clearance should be a minimum 25% of the propeller diameter. (ABS, 2021). A reduced propeller diameter may have to be selected for an increased hull clearance to solve vibration problems, but this may affect vessel performance.

- Vibration Predictions in Ship Design: should include not only an examination of the local structures for the danger of resonance but also a prediction of the vibration level. Similar to noise predictions, vibration predictions are also very useful tools for solving potential vibration problems and are recommended for use during the initial design stage.

- Evaluation and Selection of Vibration Control Treatments: include hull structure treatment, propeller treatment, and mechanical source treatment. (Dev 2017).

All the approaches above are meant to reduce noise and vibration hazards for passengers and crew. By meeting and, where possible, exceeding the mandatory and voluntary guidelines, ship builders, owners, and operators can ensure that their seafarers will have excellent accommodation and recreational facilities on board that are also consistent with promoting the safety, health and well-being of all on board. This goal is one of Bering’s very highest priorities. The efforts and measures Bering takes when it comes to acoustic and vibration harm prevention and the results of independent evaluation of these efforts are outlined in the next chapter.

Acoustic and vibration prevention at Bering

All yachts constructed by Bering Yachts go through a rigorous procedure of noise and vibration prevention design at the initial stages of development. Using computer-generated models, Bering naval architects and designers are able to predict the noise and vibration impacts of design and machinery in the yacht and create spaces and arrangements that ensure seafarer safety and comfort at the early design stages. Precise design and architectural solutions as well as using the best available equipment and machinery ensure the excellent noise and vibration prevention results for each of the yachts made by Bering.

Among the tools we use is Rockwool noise and vibration insulation, which is installed in between the floors and walls of different spaces. Sound insulation boards of different thickness are also applied depending on the needs and amounts of noise and vibration for each particular space. Building charter-class boats requires the application of thicker layers for maximum protection. Along with the Rockwool slabs, Bering uses other heavy layer materials and acoustic voids that prevent noise and vibration spreading. Acoustically rated Thermaflex products are also used for exceptional sound and vibration control, especially for protection in heating and cooling systems.

B77 Veronika – a real-life noise and vibration testing

Bering Yachts has employed an official analytics company to provide noise testing of one of its boats, a 2021-built 23,99-meter yacht Veronika, which is a standard procedure for newly built vessels at Bering. With its home in Australia, this boat has an impressive displacement of 165 tons and features a speed range between 8 and 11 knots. Testing took place in May 2021 and yielded extremely positive results.

The measurements were taken using the Bedrock SM90 equipment with the noise level measurement points located throughout the boat and measures taken in accordance with the ISO 16283-1. Noise levels were taken at anchor position and at maximum speed (@1700 RPM – 11.5 Knots). Below is the table comparing noise level recommendations from the American Bureau of Shipping, world-leading classification organizations and the results of Veronika testing.

Maximum noise levels for superyachts both for harbored and sailing conditions in comparison to B77 Veronika noise testing. Values in dB (A).

| Spaces | ABS Comfort (Y) | Bureau Veritas | Germanischer Lloyd (Cruise Ship) | Lloyd’s Register | RINA | B77 Veronika |

| Harbour Sailing | Harbour Sailing | Harbour Sailing | Harbour Sailing | Harbour Sailing | Harbour Sailing | |

| Owner Cabin | 50 53 | 40 50 | 44 52 | 50 | 45 | 23.5 54.0 |

| Guest Cabins | 50 53 | 40 50 | 46 54 | 53 | 45 | 32.0 59.8 |

| Lounges | 52 55 | 45 55 | 52 60 | 55 | 55 | 31.1 53.9 |

| External decks | 70 73 | 55 75 | 64 72 | 63 | 55 | 38.4 60.6 |

| Crew cabins | 60 65 | 45 65 | 45 60 | 29.7 52.4 |

As a result, almost all at harbor and at sailing conditions measurements of the B77 either exceed the recommended thresholds or stay within the limits for compliance measurements (within 3 dB(A) of the criteria for noise). (ABS 2016) This allows us to speak about our under-24-meter yacht as comparable to the superyacht in relation to noise safety.

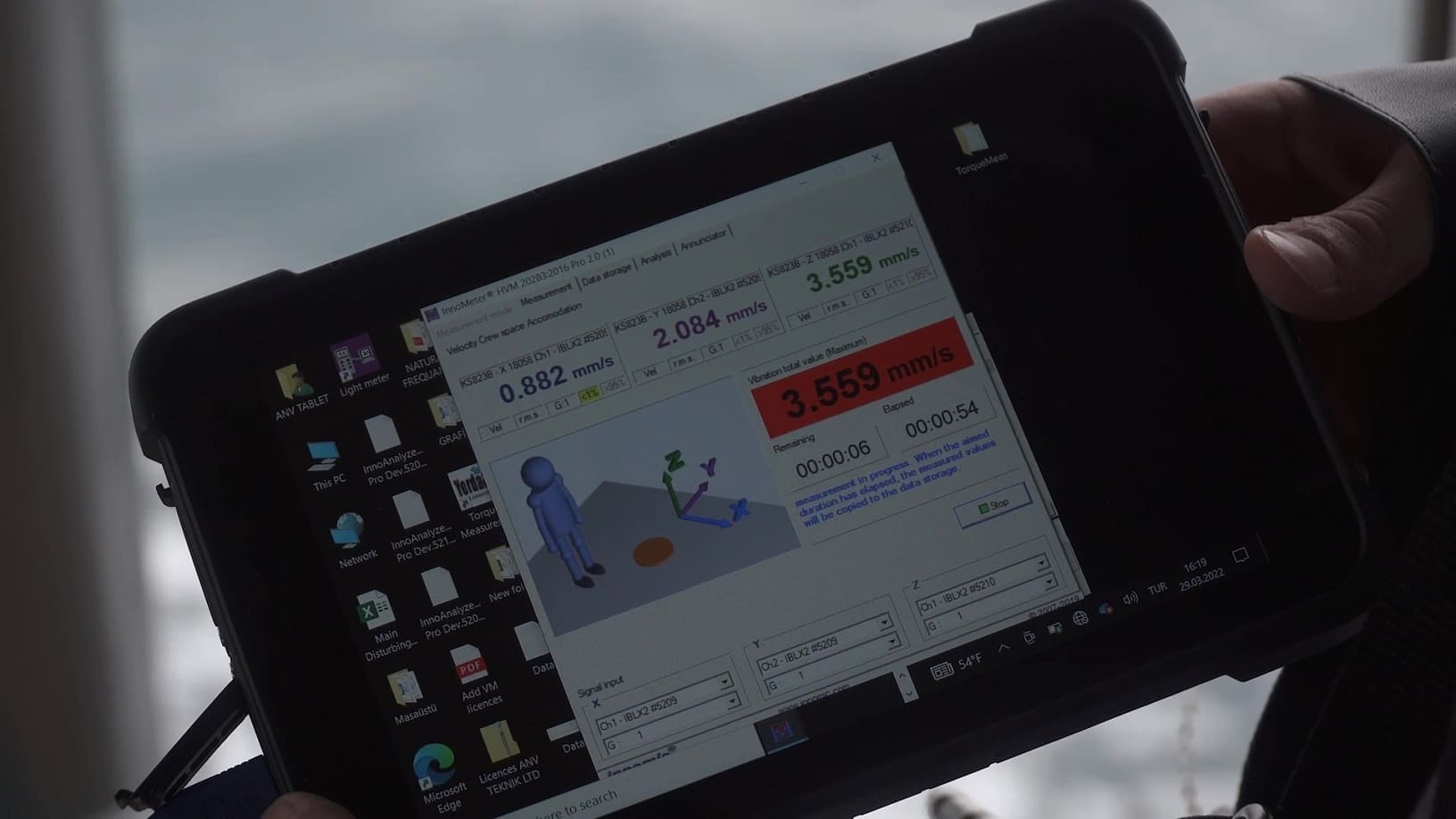

Similar results were achieved during the vibration testing. VibroMatrix InnoBeamer device and RION VA-12 portable analyzer were used to test the whole body and the inner vibration of the ship. The measurements were taken at still and at maximum speed (@1,700 rpm – 11.5 knots). The results presented in the table below, with Veronika’s vibration levels significantly lower than those set for superyachts, confirm Bering’s commitment to vibration protection.

Maximum allowable levels for vibration for superyachts in comparison to B77 Veronika vibration testing at bay and at maximum speed.

| Location | BV | Lloyds Reg | RINA | ABS Comfort (Y) | Bering 77 Veronika |

| – | ѵ (mm/s) | ѵ (mm/s) | ѵ (mm/s) | ѵ (mm/s) | ѵ (mm/s) |

| Cabin and lounge | 1.0-3.0 | 1.8-2.5 | 1.0-3.0 | 1.5-2.25 | 0.06-0.725 |

| Public spaces | 1.0-3.0 | 1.8-2.5 | 1.0-3.0 | 1.75-2.5 | 0.21-0.695 |

| Open decks | 1.0-3.0 | 1.8-2.5 | 1.0-3.0 | 2.0-2.75 | 0.023-0.323 |

Bering is dedicated to making seafarer’s life onboard as pleasant and secure as possible, and the testing confirms this. Most values of noise and vibration onboard of Bering 77 are around or better than recommended ones from the regulations related to the superyachts. Fancy design, speed, luxurious amenities are not everything. Do not forget to include noise and vibration testing in the checklist while looking at other boats you plan to buy or charter.

REFERENCES/MATERIALS PART 2

1. American Bureau of Shipping (ABS). Guide for Crew Habitability on Ships. 2016.

2. American Bureau of Shipping (ABS). Noise and Vibration Control for Inhabited Spaces. 2017.

3. American Bureau of Shipping (ABS). Comfort on Yachts. 2019.

4. American Bureau of Shipping (ABS). Ship Vibration. 2021.

5. Boote D., Blake J., Flay R., Suthreland L. ISSC Committee V. 8: Yacht Design // 18th International Ship and Offshore Structures Congress. Vol. 2. 2012. DOI: 10.13140/RG.2.1.3985.7366.

6. Bureau Veritas. Rules For the Classification of Steel Ships. Part F. Additional Class Notations. NR467. 2022.

7. Dev A., Chla Y., Tam I. Maritime Sustainability and Maritime Labour Convention – Reducing Vibration and Noise Levels on Board Ships for Health and Safety of Seafarers // Conference Paper. 2017.

8. Pais, T., Boote D., Dellepiane, S. Vibrations of Superyacht Structures: Comfort Rules and Predictive Calculations // Proceedings of the 4th International Conference on Marine Structures MARSTRUCT 2013. EID: 2-s2.0-84874466721.

9. Turan O., Helvacioglu I., Insel M., Khalid H., Kurt R. Crew Noise Exposure on Board Ships and Comparative Study of Applicable Standards // Ships and Offshore Structures. Vol. 6 Issue. 4. 323—338. DOI: 10.1080/ 17445302.2010.514716.